| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : TGMCO

Certification : SGS

Place of Origin : Jiangsu, China

MOQ : 1 set

Price : $15000-$25000/set

Payment Terms : L/C, T/T

Delivery Time : 5 sets per month

Packaging Details : Export standard sea package with film and steel, other spare parts and some small parts are packed in plywood box

Name : Downspout & Gutter Roll Forming Machine

Use : Building Material

Material : Color Steel, Galvanized

Feeding Width : 200-600mm

Material Thickness : 0.5-1.2mm

Roller Drive Type : By Chiain

Forming Station : About 12-18 stations

Main Motor Power : 5.5-7.5kw

Forming Speed : 5-15m/min

Production Speed : 5-10m/min

Roller Material : 45# steel

Shaft Diameter : Φ60-75mm

Shaft Material : 45# Steel

Cutting Blade Material : Cr12 with Quenched Treatment 60-62 °

Cutting Type : Hydralic cutting

Hydraulic Power : 3kw

Control System : PLC

PLC : Panasonic/Siemens

Warranty : 1 Year

High Speed Water Downspout Elbow Roll Forming Making Machine

High quality glazed tile IBR sheet double layer trapezoidal roof press making machine roll forming machinery is for make the roof sheet for construction.This double layer roof press making machine using for produce both glazed tile in up layer and trapezoid sheet in down layer.

Here the pictures for your reference.

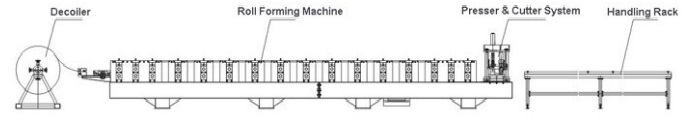

Machine components

| No. | Name | Qty |

| 1 | Decoiler | 1 set |

| 2 | Feeding | 1 set |

| 3 | Roll Forming Machine | 1 set |

| 4 | Cutting Device | 1 set |

| 5 | PLC Control System | 1 set |

| 6 | Hydraulic Station | 1 set |

| 7 | Output Table | 2 sets |

Technical parameters

| Items | Items | Specifications |

| Material of coil | Material Width | 200-600mm |

| Material Thickness | 0.5-1.2mm | |

| Decoiler | 3 tons | |

| Feeding&Leveling | 5 Rollers Leveling | 2rollers up, 3rollers down |

| Forming system | Forming Speed | 5-15m/min |

| Forming Stations | about 12-16 stations | |

| Roller Material | 45# steel | |

| Shaft diameter | 60-75mm | |

| Shaft Material | 45# steel | |

| Main Motor Power | 5.5-7.5kw | |

| Machine structure | Wall panel | |

| Transmission | By chain | |

| Cutting system | Hydraulic Power | 3kw |

| Cutting blade | Cr12Mov,quenching HRC 58-62 | |

| Tolerance | +-1.5mm | |

| Electrical control system | Electric Source | 380V, 50HZ,3 phase |

| PLC Control System | Siemens/Panasonic |

Profile Drawing

Working flow

Decoiler—Feeding—Main Roll forming—Hydraulic Cutting—Output table

Machine Components

1. Manual decoiler

1). Coil weight: max .3 tons

2). Decoiler: passive uncoiling, manual expansion

3). Expansion range:Φ480-520mm

4). Coil OD: max,1500mm

2. Feeding guide

1). Stand: qualified welded profile steel

2). Guide feeding stand: side hand wheel type

3. Maim Roll former

1). Roll former type: wallboard type and chain drive

2). Forming station: about 18 stations(depend on the actual drawing)

3). roller material: 45# steel chrome coated polishing treatment

4). Roller shaft material 45#steel, shaft diameter: Φ75mm

5). Manual screw adjusts the gap between up and down rollers to suit plate with different thickness

6). Spread width of rolling material: based on the actual width of the test plate

7). Roll former mould: 1set

8). Length tolerance ≤±1.5mm

4. Hydraulic cut off

1). Cutting type: hydraulic cut off

2). Blade material: Cr12mov quenching treatment

3). Cut-off power provided by hydraulic station

5. Bending device

1). The device can bend the downspout pipe into the required arc shape, can bend up and down or left and right. Manual change bending mould in order to change direction.

2). Bending mould material: Cr12 quenching treatment

3). Power provided by hydraulic station

6,Necking device

1). The device can reduce the downspout port and facilitate lapping.

2). Necking mould material: Cr12 quenching treatment

3). Power provided by hydraulic station

7. Exit rack: 2 sets

7. Hydraulic station

1). Hydraulic system power: 11KW

2) . Solenoid Valve of Hydraulic System: Beijing Huade (24V Safety Voltage)

3) . Hydraulic system oil pump: plunger pump

4) . Cooling mod: air cooling

8. Electric control system

1). Inverter:Yaskawa

2). PLC:Panasonic

3). Touch screen:MCGS

4). Encoder: Omron

Picture for reference

FAQ

1) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided). We have cooperated with many customers all over the world with high market reputation, no worries.

2) Q: How to choose the Tube Mill Line?

A: You have to inform us following details:

- The pipe material

- Round pipe range

- Square pipe range

- Rectangle pipe range

- Wall thickness range

- The pipe usage

3) Q: How to choose the Roll Forming Machine?

A: You have to inform us following details:

- Coil material

- Coil thickness

- Coil weight

- Cutting type

- Profiles drawings

- Other special attention

4) Q: How to choose the Slitting Line & Cut to Length line?

A: You have to inform us following details:

- Coil material

- Coil thickness

- Coil width

- Coil weight

- Finished sizes

- Other special attention

55) Q: Where is the nearest airport to your company?

A: Shanghai Putong or Hongqiao Airport.

6) Q: How about your service?

A: Before sales:

- Technical Support: TGMCO will provide detailed technical information such as technical & commercial offer, machine photos, running video, layout, operation manual, and show you working machines in our factory.

- Apply Visa: TGMCO will provide officially invitation letter to apply Visa in china embassy as authority procedures and requirements.

After sales: TGMCO provides comprehensive After Sales Support and Service to meet our customer need.

- Drawings: Provide the foundation drawing, electric scheme and wiring diagram, hydraulic drawing, pneumatic & electric pipeline drawing and other drawings requested by customer.

- Installation and commissioning: TGMCO will send our technicians to customer's workshop for supervision of installation and commission

Training of Customers' technician/workers during commission

- Breakdown Support: We offer 1 year warranty service for main crucial components except consumables

Inform immediate technical assistance and advice to customer by phone or e-mail.

Skilled and experienced engineers are capable of dealing with any type of breakdowns.

Technical service work performed in Customer's site if required.

Urgently supply mechanical or electronic components.

Fast supply of spare parts and wearing parts to cover foreseeable requirements

Packing & Delivery

|

|

Water Seamless Gutter Forming Machines Manual Downspout Elbow Machine Images |